From the time the packaging industry evolved, steel strapping became an essential part of the industry. The packaging industry could not do without steel strapping because it was the most reliable packaging material for mid duty as well as heavy duty applications. Steel strapping also received its fair share of flak for several reasons and went down a couple of notches and has been replaced by poly strapping that has proved its worth as a strong strapping material.

Earlier, steel strapping was the only choice for the packaging industry. Now, there are a variety of poly strapping options to choose from and steel is being considered as an alternative only if the required poly strapping is not available.

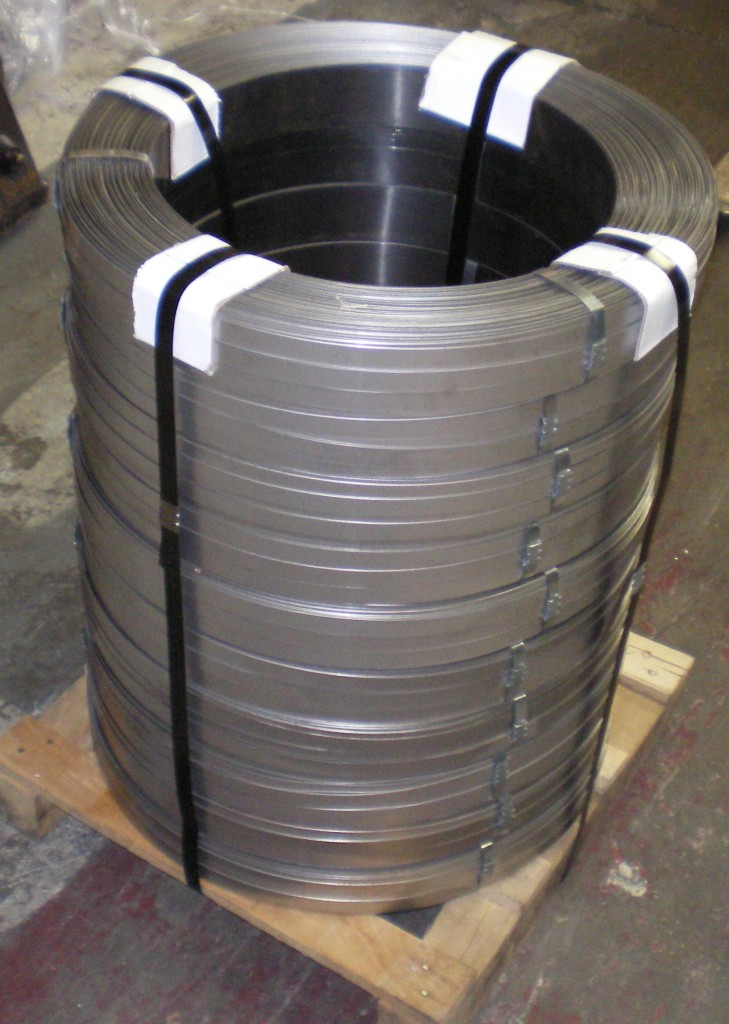

However, there a lot of steel strapping loyalists who continue to use steel banding and consider it the best for heavy duty applications. Steel banding comes in rolls of half-inch to 2 inch width and various thicknesses. It is available in regular duty and high tensile types. According to industry experts steel banding is considered relatively stable and stretches very little after application.

Advantages of Steel banding:

- Good for heavy loads

- Best for rough handling

- High tensile

- Carbon reinforced

Disadvantages:

- For inexperienced users, a safety hazard

- Can inflict deep gashes if cut carelessly

- Scratch and tear the load

- Leave scars and marks on the load

- Rust when exposed to weather elements

The advantages and disadvantages of steel strapping are almost equal. However, since most of the steel strapping is carbon reinforced many consider this a great advantage. Another advantage of steel strapping is that it comes highly recommended for loads that can be jolted during transit and as a result great break strength is required.

Another disadvantage of steel strapping is that it is more expensive than poly strapping and other strapping materials. Since cost fluctuates often depending on the price of the base metal, it can be difficult to budget. Industries that are known to rely on steel strapping and cannot switch over to poly strapping, continue to do so as they may not have budget constraints. But those industries that are able to switch over to poly strapping do so and cut their costs by almost half.

However, the reason steel strapping is holding on its own even with its disadvantages is because there is no other strapping that can hold a heavy load for long distances quite as well. Allstrap is a place where one can find all kinds of strapping in various widths and thicknesses. Call Allstrap for your strapping needs.