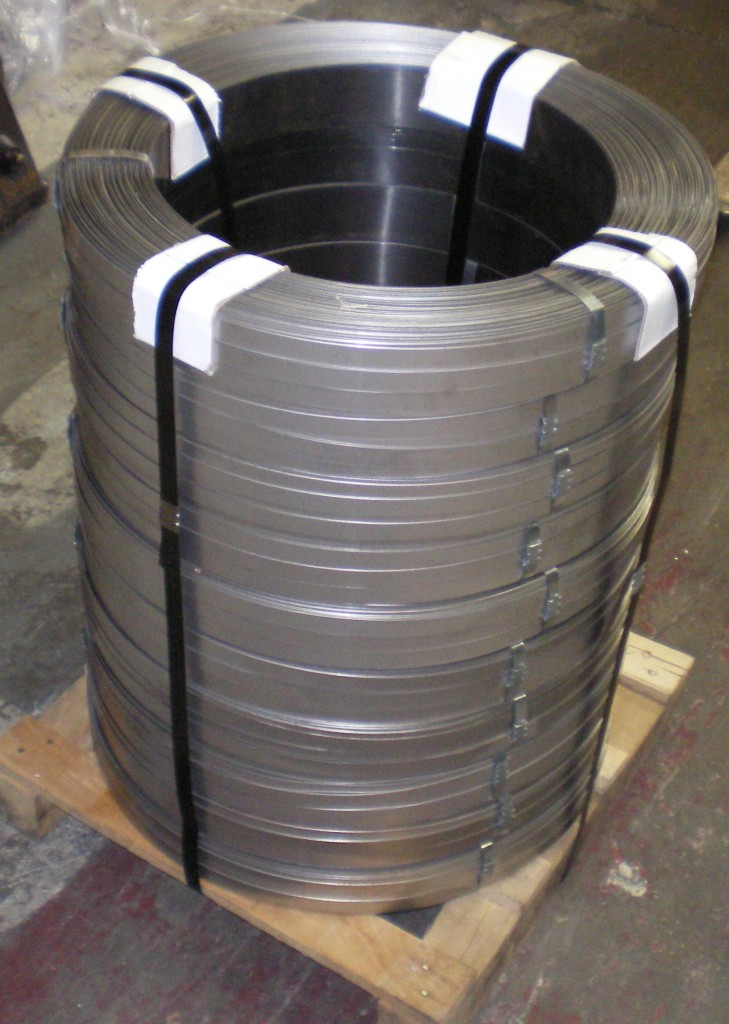

Steel strapping was the most popular option available to the industry till a few years ago. Customers wanted steel strapping because it was the strongest strapping and believed that it was the best to pack. But it does have a major flaw, and that is rust.

Unfortunately, not much can be done about this. The steel strapping will be exposed to the elements and this is mostly unavoidable. Then with a lot of design and development the stainless strapping was introduced in the market. This has proved to be an advantage to the industry as it is as strong as the steel strapping and it is more durable too.

Time and again stainless steel strapping has proved its worth. Stainless steel strapping also provides UV resistance and has a great break strength. This strapping can be used for a variety of purposes too apart from industrial use. The most commonly used stainless steel varieties are, 201, 317 and 304. The most widely used stainless steel strapping is the 201. It is the most durable and strongest of all stainless steel strapping. This steel has more tension and elasticity and it is very easy to handle.

The 317 stainless steel strapping is well known for its resistance to rusting. When compared to regular steel this is considered more resistant to corrosion as the components of this steel is a mixture of alloys. However, market indicates that this steel is less popular as it is more expensive when compared with other kinds of steel strapping. The 304 stainless steel strapping is less expensive when compared to other steel strapping and is more resistant to corrosion than the other two stainless steel strappings. This kind of stainless steel strapping has proven time and again to be the best bet for places where chemical exposure is possible.

The benefits of using Stainless steel when compared to Steel Strapping:

- Stainless steel strapping has higher break strength when compared to steel

- Stainless steel can withstand harsher climatic conditions when compared to steel

- Steel can cause damage to cargo while being packed, but stainless steel causes lesser damage.

- Steel has sharper edges and can cause cuts, whereas stainless steel is not as sharp and has a good finish.

- Steel is ideal for heavy duty cargo, stainless steel is ideal for harsh conditions and when corrosive substances are being transported.

Depending on the nature of packaging both stainless and steel strapping have their own advantages and can be put to use accordingly.